Printer Overview

Outsized Performance in a Compact Footprint.

Introducing the imagePRESS V900 Series. These light-to mid-volume production digital color presses are designed to offer impressive productivity, repeatable color, and incredible automation. The imagePRESS V900 Series’ advanced core technologies have been harnessed to allow you to realize your vision more easily and efficiently than ever.

PERFORMANCE

Keeping the press up and running is a top priority.

With the default High-Productivity Mode, you can realize high throughput on your long production runs. Plus, the imagePRESS V900 Series’ ability to hold highly accurate color and tight registration across a run with real-time adjustments mean you can experience minimal downtime. The Multi Sheet Detection of the Multi Drawer Paper Deck* automatically diverts any jam-prone sheets to a dedicated purge tray, without stopping the press or requiring operator attention.

*Optional accessories

Astounding Output

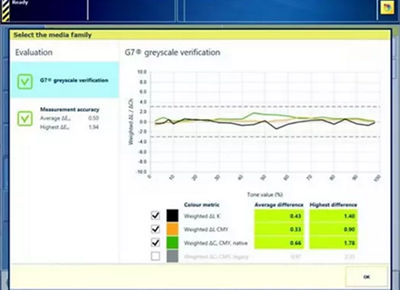

- The 2400 x 2400-dpi print resolution utilizes the unique R-VCSEL imaging technology

- ILS (Inline Spectrophotometers) allow advanced color adjustments, such as engine linearization, media calibration, color profile creation, and color validation.*

- Translucent CV Toner produces vibrant images on a wide variety of stocks.

- Multi DAT helps to achieve consistent color across long runs automatically.

*PRISMAsync print server or imagePRESS Server required

Remarkable Productivity and Flexibility

- Production speeds of up to 90 ipm

- Bring efficiency to many tasks with the ADF*

- Maximum feeding capacity of 10,400 sheets*

- Wide array of productive in-line accessories*

*Optional accessories required

Versatility

- Supports stocks up to 130 lb. Cover in weight*

- Runs a variety of envelopes, specialty, and long sheets up to 51.2″

- Achieve highly accurate and consistent registration even on large and heavy media

- Meets ENERGY STAR® certified

*Optional accessories required

SIMPLIFY WORKFLOW, EMPOWER YOUR TEAM

The PRISMAsync family of print servers helps streamline production by making printing operations more intuitive and uniform. Managing and running jobs through multiple presses more easily than ever before. Plan-ahead up to 8 hours of production with the Job Scheduler. The intuitive interface helps operators easily manage jobs from composition to media to production to finishing—even those inevitable last-minute changes. PRISMAremote Manager features a dynamic user interface that allows Apps to be dragged, dropped and scaled to create a customized view with only the information your operators require!

PRISMA Workflow Solutions

PRISMA is Canon’s family of workflow solutions designed to help optimize your print operation while positioning you for further growth. PRISMA workflow solutions include on-premise and cloud-based solutions to simplify job submission, accelerate document preparation, facilitate order and production management as well as tools designed to help support performance monitoring, cost allocation and color management.

WHITE PAPER IN-FINISHED PRODUCT OUT

Keep more jobs in house-and with less effort-by selecting from an extensive array of Canon and third-party in-line finishing options that offer punching. Wire-binding, booklet-making, and trimming. Inline feeding and finishing options are essential for print environments to achieve maximum versatility and flexibility when producing high-quality, professional print applications including brochures, manuals, reports, and books, among other materials.